Welcome

Choosing an organization to approve a management system is no small decision but we understand that there are plenty of choices. That’s why we work hard every day to win our customer’s confidence and loyalty.

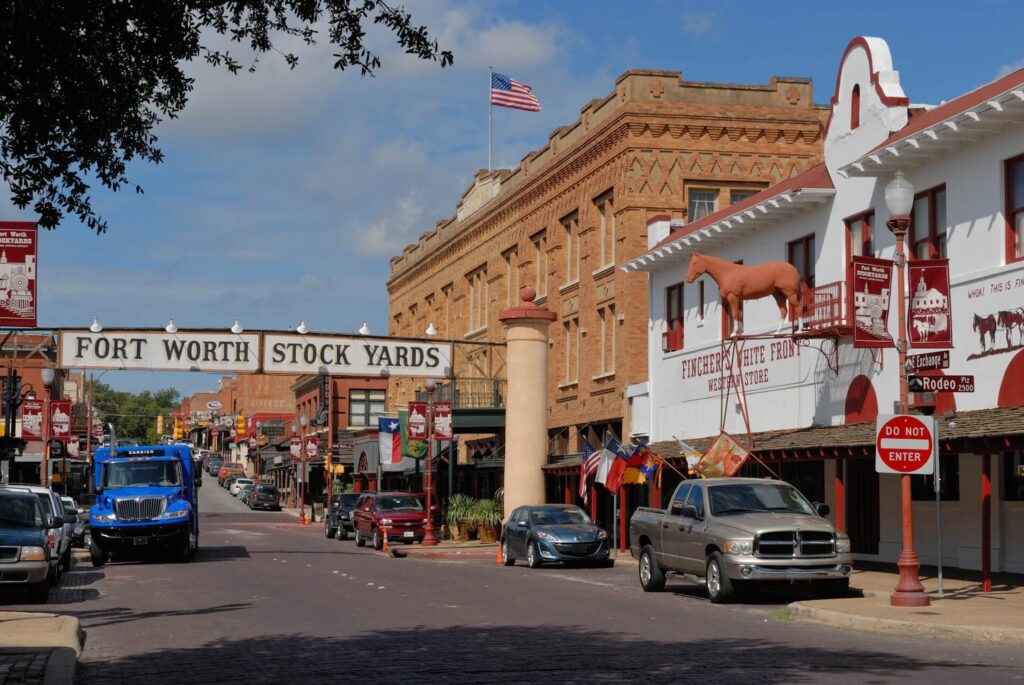

Dedication to transparency and consistency in everything we do has been a hallmark of ISO Pros in Fort Worth, Texas (TX) since we were established. So it’s no surprise that we have such a consumer satisfaction rating and that our auditors have been with us for so many years. We’ve continued to be the most popular throughout the years, and probably the most reliable and trustworthy registrar that you’ll find.

If you are a big international corporation conducting business on several continents, or a tiny enterprise with less than 5 workers, ISO Pros in Fort Worth, Texas (TX) would represent you very well.

Here are just some of the advantages of working with us:

- A customer-first mindset that prioritizes their goals

- A deep dedication to honesty and ethics in the course of the certification

- Certification of integrated service operations with quality and risk reduction requirements

- Audits which seek to generate value for your organization

- A lasting partnership with a professional registrar that can stick with you for the long term

- Bottom line results which come with having a trusted registrar certification

ISO 45001

The ISO 45001 standard defines criteria for a management program for occupational health and safety (OH&S) that helps companies to monitor the risks associated with OH&S and increases efficiency. This does not specify basic success requirements for OH&S, nor does it provide clear parameters for a management system design.

ISO 45001 reflects the latest universal standard for workplace health and safety administration and replaces OHSAS 18001. To improve occupational health, the standard now reduces the risks in the workplace.

Gaining ISO 45001 certification helps you to show that your company maintains a best practice Occupational Health and Safety Compliance Program – reducing the risk of injuries and infringements of regulations, as well as enhancing the overall efficiency of the organization.

This standard meets other established health and safety requirements as it was produced by a group of specialists on workplace health and safety. This takes into account other universal guidelines in this field such as OHSAS 18001, the ILO-OSH Standards of the International Labor Organization, numerous national requirements, and the international labor laws and conventions of the ILO. Which makes it one of the most important tools used to date, for health and safety administration.

Certification and training

Improve performance and control risk with ISO Pros in Fort Worth, Texas (TX) certification in ISO 45001. After the first version was written in 1999 there have been a variety of essential improvements to the text. According to drafters, the revisions represent the standard’s extensive adoption and practice in more than 80 countries and by over 16,000 accredited organizations.

There is also an even stronger focus on “health” rather than only “safety,” and substantially strengthened compliance with the environmental management systems ISO 14001 to support the definition of integrated management systems.

What is ISO 9001 for?

ISO 9001 specifications provide you with a framework for building a quality management system that supports your goal of continuous improvement. You set your own goals, but the company builds a stronger management capability to improve its processes and activities by following a series of concepts (such as Plan-Do-Check-Act). The standard lays out a risk-based control strategy to ensure, first and foremost, that you work on the priority areas.

ISO 9001

ISO 9001 for Quality Management Systems is the most common and accepted quality standards. There are over 1,000,000 businesses and organizations globally certified according to the ISO 9001 standard. For businesses that start off on the ISO 9001 path, though, they’ll always ask the following questions ‘What is ISO 9001? And What can it do for my business? ISO Pros experts are here to help answer any questions you may have.

ISO 9001 is an international standard that sets out certain requirements for companies to include in a Quality Management System (QMS). Those standards mean that the company, today and in the future, will satisfy its client base. ISO 9001 reflects on procedures that influence the consistency of the services and products they deliver to ensure that they are compliant and compatible with relevant specifications. The question ‘What is ISO 9001’ has many mistaken assumptions, in that people believe they should purchase a book or a set of documents and simply present them to an inspector for approval.

ISO 14001

ISO 14001 is the International Standard used by organizations to improve their performance and their impact on the environment. ISO 14001 focuses on the identification of major risks and challenges to the environment. Using good data from an initial assessment would offer transparency and require a priority to be put in place for areas that will gain the most from environmental efficiency, but if a minimum set of controls is established by-laws or legislation, these will also be in effect.

ISO 14001 does not set environmental performance standards, but it allows an organization to define and control its own environmental aspects. The applicability of the requirement will be checked by an external audit, which makes sure that you have correctly defined these standards.

Implement ISO 14001 with ISO 9001

Adding a QMS that satisfies ISO 14001 environmental criteria within an established ISO 9001 compliance program has never been as easy as with the updates to the latest version of these two standards. Organizations with a rigorous and comprehensive quality management system would appreciate the need for reliable data and evidence so they will not foresee a problem that can be easily overcome by adding a new dimension to their overall management system. Organizations that work with manufacturers are constantly demanding evidence of environmental policies or compliance according to ISO 14001.

It could be an acceptable requirement in certain circumstances, although there have been a variety of recent instances where we have seen ‘optional’ become more ‘required.’ This has been especially true in the case of production, and specifically where electronics or plastics are concerned because they need to show environmental requirements to the public who are becoming savvier about the environment.

ISO 13485

This standard was developed by the International Standards Organization to include the specifications for the development and management of quality programs for medical device companies. Although medical technology firms in the US are legally obligated to be compliant with the FDA quality control regulations listed in the 21 CFR Section 820, businesses seeking to sell medical devices across foreign markets such as Canada or Europe are expected to obtain ISO 13485 approval. U.S. producers can also pursue ISO 13485 approval, although that is not mandatory when the company wants to sell its goods internationally.

How ISO 13485 compares with FDA QSR

Although ISO 13485 designation is a standard for the sale of medical devices both in Canada and in the EU, the United States controls the safety of medical devices by FDA administrative regulation. The new revision for ISO 13485 was created with the FDA, and because of this, the two papers are very close in certain ways. For starters, the parts that address Development Controls in each paper are nearly identical.

Even with their similarities, their requirements do not completely overlap with ISO 13485 as well as FDA QSR. A QMS that’s ISO 13485 certified may not fulfill FDA regulations’ complaint handling criteria and post-market inspection and complaint handling procedure. In comparison, ISO 13485 is seeking an approach that is more risk-based to the QMS.

AS9100

The AS9100 is an international standard for aerospace that defines specifications for a QMS where a company wants to show the capacity to reliably produce a product that satisfies the legislative and regulatory criteria relevant to the customer. Many producers and suppliers in the aerospace industry across the globe need AS9100 Certification as a prerequisite for doing business with them.

Who needs AS9100?

Any aerospace supply chain organization will take advantage of the AS 9100 certification including:

- Manufacture and design of equipment

- Supply of the airplane accessories,

- Supplying spare parts,

- Repair, facility and aircraft maintenance and overhaul services

Benefits

- Aerospace businesses recognize this certification.

- Certified organizations are accepted into the OASIS (Online Aerospace Manufacturer Information System) portal, which allows for competitive advantage.

- Improved processes and practices can contribute to cost-savings and efficiencies.

How does AS 9100 align with ISO 9001

ISO Pros in Fort Worth, Texas (TX) will help you conduct a gap analysis between the ISO 9001 compliance framework and the AS 9100 specification to determine additional criteria that need to be fulfilled in order to obtain certification successfully. Our experts in AS 9100 will support you throughout the process. They will assist you to obtain approval and maintain the AS 9100 system using improvements and internal audits.

These benefits include:

- Reduced costs, which would contribute to better efficiency of the product and operation

- Increases confidence in your company. As you compete on multinational procurement contracts you would have more confidence to be able to fulfill the contract.

- It may help to minimize or remove numerous appraisals among certain vendors who already are expected to satisfy more than one collection of supplier specifications.

- You can become the supplier of preference. It lets you win contracts with several of the world’s leading car suppliers as IATF 16949:2016 certification is normally a contractual obligation

- As it is based on ISO 9001, it is simpler to align into current management framework requirements.

IATF 16949

IATF 16949 seeks to establish a QMS that allows for continuous improvement, stressing the elimination of errors and reducing variability and duplication in the supply chain for automobiles. IATF 16949 refers to the design and development, manufacturing, and, where applicable, installation, and maintenance of goods relating to automobiles.

Certification according to IATF 16949 provides a major potential for standardization and development for companies operating within the automotive industry. If you are obligated to seek certification to this standard contractually or if you are seeking to develop a new company or just wanting to reach new industries, certification to this standard provides substantial benefits.

CMMC

The United States Department of Defense (DoD) will now expect companies doing business with the DoD (i.e., military contractors) to receive an impartial assessor’s review for Cybersecurity Maturity Model Certification (CMMC). This is supposed to affect the entire Defense Industrial Base (DIB). How are contractors expected to do to prepare their companies for these latest requirements?

The development and certification of cybersecurity controls entail a time-consuming investment of resources, both in terms of manpower and funds, depending on the appropriate CMMC maturity level. It heightens the need to move quickly rather than delay it. You can confidently address the CMMC challenges pragmatically by using the experience we have at ISO Pros in Fort Worth, Texas (TX).

CMMC’s implementation is a big change in the legislative technology environment, which could have important effects on all types of defense contractors. In order to do business with the DoD, because of the introduction of this model, it effectively means that all defense contractors would be expected to obtain a given CMMC level, requiring a certification to be carried out by an impartial and trained third-party assessor.

The DoD would not only allow military contractors to fulfill these new standards, it will also flow these specifications throughout their supply chains, bringing increased subcontract oversight and risk pressures on higher-tier contractors.

The use of the CMM paradigm in software creation has also become troublesome. Applying various frameworks that are not standardized inside and across an organization may be expensive for preparation, appraisal, and enhancement. The Capacity Maturity Model Integration (CMMI) concept was developed to address the issue of utilizing different models for software development processes, and the CMMI model has substituted the CMM model, while the CMM model remains a generic technical process functionality model that is used in the public domain.

Originally, the CMM was designed as a method for evaluating federal contractors’ abilities to execute a software contract project. While it comes from the field of software engineering, it may be, has been and tends to be commonly used in IS / IT (and other) companies as a general concept of process complexity (e.g., IT service management processes).

CMMI

Capability Maturity Model is a standard for assessing the complexity of a software process in an organization. This is a technique that is used to build and improve the software development process of an organization. CMM may be used to measure an organization depending on its main process areas (KPA) on a continuum of five process sophistication levels. It defines the company’s maturity depending on the initiative that the business is working on and its clients. Each level will rank the company in the subject area being measured due to the standardization of its processes.